Please Choose Your Language

T: +86-18906892820

F4-19037-6#, Yiwu Intl Trade Mart, Yiwu Jinhua, Zhejiang, China (Mainland)

Views: 354 Author: Site Editor Publish Time: 2025-07-04 Origin: Site

When selecting Load Break Tools for power distribution systems, one of the most critical factors to consider is the voltage rating. The voltage rating determines the tool’s ability to safely interrupt electrical currents without causing damage or posing hazards during operation. Using a load break tool with an inappropriate voltage rating can lead to equipment failure, unsafe working conditions, and costly downtime.

Proper voltage matching ensures that the tool can withstand the electrical stresses present during load switching and fault conditions. It also guarantees compatibility with the existing power infrastructure, preventing unexpected arc flash incidents or insulation breakdowns. Therefore, understanding and choosing the correct voltage rating is essential for both safety and operational reliability in any electrical maintenance or switching task.

When selecting Load Break Tools, it’s essential to understand the different voltage ratings that define their performance and safety. Two key terms frequently encountered are Nominal Voltage and Maximum Rated Voltage, each serving a distinct purpose in equipment specification.

Nominal Voltage refers to the standard or rated operating voltage for which the tool is designed. This value represents the typical voltage level under normal operating conditions. For instance, common nominal voltage classes for load break tools include 15 kV, 25 kV, and 35 kV, which correspond to various medium-voltage distribution systems.

On the other hand, Maximum Rated Voltage indicates the highest voltage the tool can safely withstand during transient events such as switching surges or fault conditions. This rating is always higher than the nominal voltage to provide a safety margin. For example, a load break tool with a nominal voltage of 25 kV might have a maximum rated voltage of 27 kV or more.

During load switching operations, the tool must be capable of interrupting current and voltage without causing electrical breakdown or arcing. Therefore, the tool’s insulation and construction must meet these voltage ratings to ensure reliable and safe operation. Using a load break tool with inadequate voltage ratings risks equipment failure, dangerous arcing, and potential harm to operators.

Understanding these voltage parameters helps electrical engineers and maintenance personnel select the right tool tailored to their system’s requirements, enhancing both safety and longevity of the power distribution network.

Choosing the appropriate voltage rating for Load Break Tools largely depends on the specific environment and application in which they will be used. Different power systems have varying voltage demands, which dictate the selection of tools to ensure safety and functionality.

Medium voltage (MV) systems typically operate within the range of 1 kV to 36 kV and are common in local distribution networks. Load break tools designed for MV applications often have nominal voltage ratings such as 15 kV, 25 kV, or 35 kV, matching the system’s operational requirements.

High voltage (HV) systems, which exceed 36 kV, require specialized equipment beyond standard load break tools and are generally handled with more advanced switchgear solutions.

For overhead power lines, load break tools with nominal voltages around 15 kV to 25 kV are commonly used. These tools are designed for ease of use with hot sticks and offer the insulation needed to safely operate in exposed environments. The voltage rating must correspond to the line’s operating voltage to prevent electrical faults and ensure operator safety.

Underground distribution typically involves enclosed and insulated cables with voltage ratings similar to overhead systems, often between 15 kV and 35 kV. Load break tools for these applications must be compatible with pad-mounted switchgear or vault installations and provide reliable operation in confined spaces with adequate voltage rating.

Emerging energy sources such as wind farms and solar parks often integrate medium voltage distribution equipment, requiring load break tools rated accordingly. Depending on the design and scale, these tools may need to support voltages in the 15 kV to 35 kV range, ensuring safe switching and maintenance operations within renewable energy infrastructure.

Selecting the correct voltage rating based on the application environment ensures that load break tools operate effectively without compromising safety or performance, ultimately supporting reliable power delivery across diverse electrical networks.

Selecting a Load Break Tool with an inappropriate voltage rating can lead to serious safety hazards and operational inefficiencies. Understanding these risks is crucial for maintaining a safe and reliable power distribution system.

When a load break tool is operated on a system with a voltage higher than its rated capacity, it may fail to safely interrupt the circuit. This can cause dangerous arc flash events, where an uncontrolled electrical discharge poses severe risks to personnel and equipment. Additionally, undervalued tools may trigger unintended tripping or system faults, leading to unplanned outages and costly downtime.

While selecting a tool with a voltage rating higher than required generally poses fewer safety risks, it can result in unnecessary costs and inefficient use of resources. Higher-rated tools are often bulkier, more expensive, and may not offer optimal performance for lower voltage systems. Over-specification can thus increase capital expenditure without delivering proportional benefits.

Balancing the voltage rating precisely to your application ensures operational safety, cost efficiency, and system reliability. Always consult technical specifications and industry standards to select load break tools that match your system’s exact voltage requirements.

When selecting Load Break Tools, adherence to recognized industry standards is crucial for ensuring product safety, reliability, and interoperability. Standards such as IEC (International Electrotechnical Commission), ANSI (American National Standards Institute), and IEEE (Institute of Electrical and Electronics Engineers) specify stringent requirements for voltage ratings, insulation, arc interruption capability, and mechanical durability.

These standards define test procedures and performance criteria that load break tools must meet to be considered safe for field use. Choosing certified tools ensures compliance with national and international regulations, reduces operational risks, and enhances confidence in long-term performance. Additionally, certified products often simplify regulatory approval processes for utilities and contractors.

Therefore, always prioritize load break tools that carry relevant certifications from trusted bodies like IEC, ANSI, or IEEE to guarantee quality and safety.

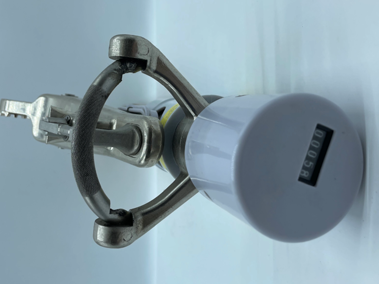

To illustrate the importance of matching voltage ratings with application needs, consider two popular products from Sasun International Electric Co., Ltd.:

SL-25 Load Break Tool

Nominal Voltage: 14.4 kV / 25 kV

Maximum Voltage: 27 kV

Suitable for medium-voltage distribution networks operating around 25 kV, commonly used in overhead and underground applications requiring reliable load interruption.

SL-35 Load Break Tool

Nominal Voltage: 25 kV / 34.5 kV

Maximum Voltage: 38 kV

Designed for higher voltage systems, typically up to 35 kV nominal, ideal for more demanding environments or networks with higher voltage ratings.

Selecting between these tools depends on your system’s voltage requirements, operational environment, and switching demands. By choosing the right model, you ensure optimal performance, safety, and cost-effectiveness in your power distribution operations.

Choosing the correct voltage rating for Load Break Tools is vital to ensure both the safety of power distribution operations and the longevity of your equipment. Using tools that meet precise voltage specifications helps prevent serious electrical hazards such as arc flashes and equipment failures, while also improving overall maintenance efficiency.

For optimal results, it’s highly advisable to consult with trusted manufacturers like Sasun International Electric Co., Ltd. Their extensive experience and wide range of certified load break tools allow you to find the perfect match for your system’s voltage and operational needs. By partnering with a reputable supplier, you not only enhance workplace safety but also boost the reliability and performance of your entire electrical network.

To explore Sasun’s advanced load break tool solutions and get expert guidance tailored to your applications, visit www.loadbreaktools.com or contact their team directly. Investing in quality tools today safeguards your operations for the future.